[ The PC Guide | Systems and Components Reference Guide | Hard Disk Drives | Construction and Operation of the Hard Disk | Hard Disk Platters and Media ]

Platter Substrate Materials

The magnetic patterns that comprise your data are recorded in a very thin media layer on the surfaces of the hard disk's platters; the bulk of the material of the platter is called the substrate and does nothing but support the media layer. To be suitable, a substrate material must be rigid, easy to work with, lightweight, stable, magnetically inert, inexpensive and readily available. The most commonly used material for making platters has traditionally been an aluminum alloy, which meets all of these criteria.

Due to the way the platters spin with the read/write heads floating just above them, the platters must be extremely smooth and flat. With older, slower spindle drives and relatively high fly heights, the uniformity of the platter surface was less of an issue. Now, as technology advances, the gap between the heads and the platter is decreasing, and the speed that the platters spin at is increasing, creating more demands on the platter material itself. Uneven platter surfaces on hard disks running at faster speeds with heads closer to the surface are more apt to lead to head crashes. For this reason many drive makers began several years ago to look at alternatives to aluminum, such as glass, glass composites, and magnesium alloys.

|

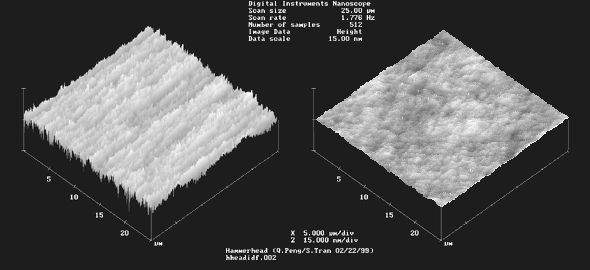

Hard disk platters are very smooth, right? Well, not to

a scanning electron microscope! |

Composed from two original images � IBM Corporation |

It now is looking increasingly likely that glass and composites made with glass will be the next standard for the platter substrate. IBM has been shipping drives with glass platters for several years and in 2000 is introducing them into the IDE/ATA consumer drive market. Compared to aluminum platters, glass platters have several advantages:

- Better Quality: The first and most important reason for going to glass is probably that glass platters can be made much smoother and flatter than aluminum, improving the reliability of the hard disk and making low flying heights and faster spindle speeds more feasible.

- Improved Rigidity: Another important consideration is that glass is more rigid than aluminum for the same weight of material. Improved rigidity, one of the reasons why platter sizes are also shrinking in size, is important for reducing noise and vibration with drives that spin at high speed.

- Thinner Platters: The enhanced rigidity of glass also allows platters to be made thinner than with aluminum, allowing more platters to be packed into the same drive dimensions. Thinner platters also weigh less, reducing spindle motor requirements and reducing start time when the drive is at rest.

- Thermal Stability: When heated, glass expands much less than does aluminum. With some hard disk platters now containing 35,000 tracks per inch or more, even a small amount of expansion can causes these tracks to "move around". The drive's servo mechanism compensates for expansion and contraction, but it is still preferable to use materials that move as little as possible because this reduces the amount of adjusting the hard drive has to do, improving performance.

One obvious disadvantage of glass compared to aluminum is fragility, particularly when made very thin. For this reason some companies are experimenting with glass/ceramic composites. One of these is a Dow Corning product called MemCor, which is a glass made with ceramic inserts to reduce the likelihood of cracking. Sometimes these composites are just called "glass", much the way aluminum alloy platters, which usually contain other metals, are just called "aluminum".

![]() Next: Magnetic Media

Next: Magnetic Media

| The PC Guide

(http://www.PCGuide.com) Site Version: 2.2.0 - Version Date: April 17, 2001 © Copyright 1997-2004 Charles M. Kozierok. All Rights Reserved. |

Not responsible for any loss resulting from the use of this site. Please read the Site Guide before using this material. |