[ The PC Guide | Systems and Components Reference Guide | Hard Disk Drives | Construction and Operation of the Hard Disk | Hard Disk Read/Write Heads | Hard Disk Read/Write Head Technologies ]

(Anisotropic) Magnetoresistive (MR/AMR) Heads

The newest type of technology commonly used in read/write heads is much more of a radical change to the way the read/write head works internally than the earlier advances, which were much more evolutionary and more related to how the head was made than how it worked. While conventional ferrite or thin film heads work on the basis of inducing a current in the wire of the read head in the presence of a magnetic field, magnetoresistive (MR) heads use a different principle entirely to read the disk.

![]() Note: The correct

technical name for first-generation MR heads is anisotropic magnetoresistive

(AMR), but traditionally they have just been called "magnetoresistive" (MR).

With GMR heads now on the market, there is the

potential for confusion between the terms "magnetoresistive" and "giant

magnetoresistive". Therefore, some companies have now gone back to calling the older

MR heads "AMR" heads to distinguish them from GMR ones. Normally though, if you

are told a drive has "MR heads", this means the older technology described here.

Note: The correct

technical name for first-generation MR heads is anisotropic magnetoresistive

(AMR), but traditionally they have just been called "magnetoresistive" (MR).

With GMR heads now on the market, there is the

potential for confusion between the terms "magnetoresistive" and "giant

magnetoresistive". Therefore, some companies have now gone back to calling the older

MR heads "AMR" heads to distinguish them from GMR ones. Normally though, if you

are told a drive has "MR heads", this means the older technology described here.

An MR head employs a special conductive material that changes its resistance in the presence of a magnetic field. As the head passes over the surface of the disk, this material changes resistance as the magnetic fields change corresponding to the stored patterns on the disk. A sensor is used to detect these changes in resistance, which allows the bits on the platter to be read.

The use of MR heads allows much higher areal densities to be used on the platters than is possible with older designs, greatly increasing the storage capacity and (to a lesser extent) the speed of the drive. Because the MR head is not generating a current directly the way standard heads do, it is several times more sensitive to magnetic flux changes in the media. This allows the use of weaker written signals, which lets the bits be spaced closer together without interfering with each other, improving capacity by a large amount.

MR technology is used for reading the disk only. For writing, a separate standard thin-film head is used. This splitting of chores into one head for reading and another for writing has additional advantages. Traditional heads that do both reading and writing are an exercise in tradeoffs, because many of the improvements that would make the head read more efficiently would make it write less efficiently, and vice-versa. For example, if you increase the number of windings of wire around the core of a standard read/write head, you increase the sensitivity of the head when reading, but you make it much more difficult to write at high speed. Also, for best results we want to write a wider data track (to ensure the media is properly magnetized) but read a narrower one (to make sure we don't accidentally pick up signals from adjacent bits). In an MR design the MR head does the reading, so the thin film write head can be optimized solely for writing without worrying about these sorts of compromises.

|

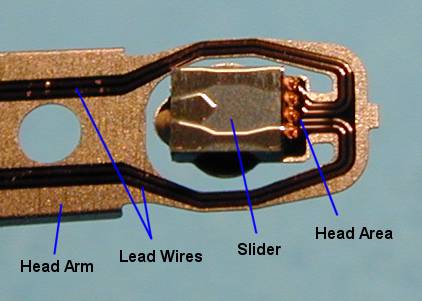

Closeup view of an MR head assembly. Note that the

separate |

First introduced in 1991 by IBM--who else--but not used widely until several years later, MR heads were one of the key inventions that led to the creation of hard disks over 1 GB in size, and the subsequent explosive growth in size since then. Despite the increased cost of MR heads, they have now totally replaced thin film heads, which just are not up to the challenge of hard disks in the tens of gigabytes. MR heads are commonly found in hard disks from about 1 GB to about 30 GB in size.

Even MR heads however have a limit in terms of how much areal density they can handle. Successive generations of MR heads were reduced in size to allow still greater areal density. Sometimes these more advanced designs were dubbed MRX for Extended Magnetoresistive heads. The successor to MR now appears to be GMR heads, named for the giant magnetoresistive effect. They are similar in basic concept to MR heads but are more advanced; GMR heads are discussed here.

![]() Next: Giant Magnetoresistive (GMR) Heads

Next: Giant Magnetoresistive (GMR) Heads

| The PC Guide

(http://www.PCGuide.com) Site Version: 2.2.0 - Version Date: April 17, 2001 © Copyright 1997-2004 Charles M. Kozierok. All Rights Reserved. |

Not responsible for any loss resulting from the use of this site. Please read the Site Guide before using this material. |