[ The PC Guide | Systems and Components Reference Guide | Hard Disk Drives | Construction and Operation of the Hard Disk | Hard Disk Read/Write Heads | Hard Disk Read/Write Head Technologies ]

Giant Magnetoresistive (GMR) Heads

From the beginning in the 1950s and its first hard disk drive, IBM has been at the forefront of hard disk technological advances. IBM's groundbreaking research and development efforts continue, nearly 50 years later, with the introduction of giant magnetoresistive (GMR) hard disk read heads. These heads work on the same general principles as the original (anisotropic) magnetoresistive heads, but use a somewhat different design that makes them superior in several ways.

GMR heads are not named "giant" because of their size; they are actually smaller than the regular (A)MR heads developed by IBM many years earlier. Rather, they are named after the giant magnetoresistive effect, first discovered in the late 1980s by two European researchers, Peter Gruenberg and Albert Fert, who were working independently. Working with large magnetic fields and thin layers of various magnetic materials, they noticed very large resistance changes when these materials were subjected to magnetic fields. These early experiments used techniques and materials that were not suitable to manufacturing, but they formed the basis for the technology.

From there, engineers and scientists at IBM's Almaden Research Center took over. IBM developed GMR into a commercial product by experimenting with thousands of different materials and methods. A key advance was the discovery that the GMR effect would work on multilayers of materials deposited by sputtering, the same technique used to make thin film media and thin film read/write heads. By December 1997, IBM had introduced its first hard disk product using GMR heads, and areal density records have been looking over their shoulders nervously ever since.

|

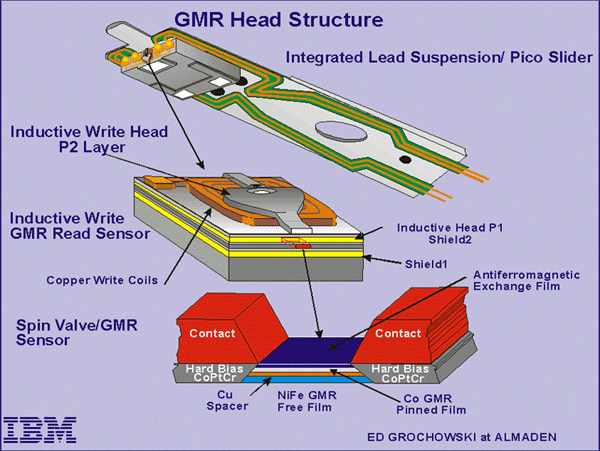

Detailed structure diagram of a GMR head assembly.

Notice how small these devices are: the |

Original image � IBM Corporation |

GMR heads are comprised of four layers of thin material sandwiched together into a single structure:

- Free Layer: This is the sensing layer, made of a nickel-iron alloy, and is passed over the surface of the data bits to be read. As its name implies, it is free to rotate in response to the magnetic patterns on the disk.

- Spacer: This layer is nonmagnetic, typically made from copper, and is placed between the free and pinned layers to separate them magnetically.

- Pinned Layer: This layer of cobalt material is held in a fixed magnetic orientation by virtue of its adjacency to the exchange layer.

- Exchange Layer: This layer is made of an "antiferromagnetic" material, typically constructed from iron and manganese, and fixes the pinned layer's magnetic orientation.

Here's how the GMR head works in a nutshell (without getting into quantum physics that would make your brain melt--and mine. :^) ) When the head passes over a magnetic field of one polarity (say, a "0" on the disk), the free layer has its electrons turn to be aligned with those of the pinned layer; this creates a lower resistance in the entire head structure. When the head passes over a magnetic field of the opposite polarity ("1"), the electrons in the free layer rotate so that they are not aligned with those of the pinned layer. This causes an increase in the resistance of the overall structure. The resistance changes are caused by changes to the spin characteristics of electrons in the free layer, and for this reason, IBM has named these structures spin valves. If you imagine a plumbing pipe with a rotatable shut-off valve, that's the general concept behind the name.

|

Conceptual operation of a GMR head, showing the four

layers. As the head moves across |

Original image � IBM Corporation |

GMR heads are superior to conventional MR heads because they are more sensitive. While older MR heads typically exhibit a resistance change when passing from one magnetic polarity to another of about 2%, for GMR heads this is anywhere from 5% to 8%. This means GMR heads can detect much weaker and smaller signals, which is the key to increasing areal density, and thus capacity and performance. They are also much less subject to noise and interference because of their increased sensitivity, and they can be made smaller and lighter than MR heads. GMR heads are also typically fitted with "shields" that prevent them from being affected by stray magnetic fields, i.e., anything but the bit directly below the head.

GMR heads are used in the latest technology drives, which currently have capacities of up to 75 GB and areal densities of approximately 10 to 15 Gbits/in2. As of early 2000, IBM has already produced GMR heads in the lab capable of 35 Gbits/in2, suggesting that standard form factor hard disks of 200 GB and up are just around the corner.

![]() Tip: 99% of the Java and

Shockwave stuff on the Web is fluffy, superfluous nonsense, but this page of IBM Research

GMR head animated demos proves that animation on the WWW can be educational, and

not just annoying.

Tip: 99% of the Java and

Shockwave stuff on the Web is fluffy, superfluous nonsense, but this page of IBM Research

GMR head animated demos proves that animation on the WWW can be educational, and

not just annoying.

![]() Next: Colossal Magnetoresistive (CMR) Heads

Next: Colossal Magnetoresistive (CMR) Heads

| The PC Guide

(http://www.PCGuide.com) Site Version: 2.2.0 - Version Date: April 17, 2001 © Copyright 1997-2004 Charles M. Kozierok. All Rights Reserved. |

Not responsible for any loss resulting from the use of this site. Please read the Site Guide before using this material. |