[ The PC Guide | Systems and Components Reference Guide | Keyboards | Keyboard Construction and Operation | Keyswitches ]

Mechanical Contact Keyswitches

The simplest keyswitch technology in conceptual terms, mechanical contact keyswitches are "classical" switches, working in much the same way that many other types of switches do in the world around us. They work simply on the basis of two contacts mechanically touching each other to complete a circuit, not unlike a doorbell in some ways.

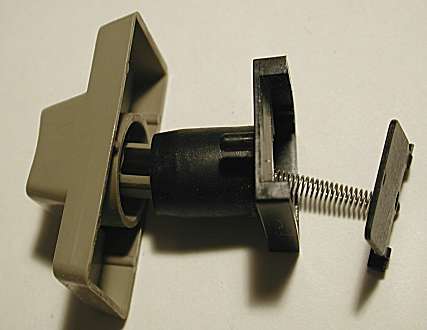

In some designs, the mechanical keyswitch uses two metal contacts, made of a non-corroding, high-conductance material (the best designs use gold-plated contacts, which of course isn't cheap). These are separated by a plastic piece that hold them apart, and a spring used to keep the plastic in place and hold the key in its default position. When you press down on the key, the plastic pivots out of the way, and the contacts move towards each other and touch, completing the circuit. When you release the key, the energy stored in the spring reverses the process, opening the circuit as the keycap rises back to its normal place. In other designs, a metal piece is mechanically pushed down to touch contacts on a circuit board to register a keypress.

One problem with this sort of design is that you don't get much in terms of tactile feedback or audibility just by having two metal contacts close a gap and touch each other. As a result, this type of keyswitch usually includes additional hardware to create an audible and tangible "click" as the key is depressed. This negates some of the "simplicity" of the basic design of course.

|

Exploded closeup view of a mechanical keyswitch. The

keycap |

The chief advantage of mechanical keyswitches is that they are rather durable, typically rated for tens of millions of activations. Their main disadvantage is cost: they are expensive to manufacture. They are not common in modern PC keyboards, but many people consider them to be desirable due to their solid feel and strong tactile feedback.

![]() Next: Foam and Foil Contact Keyswitches

Next: Foam and Foil Contact Keyswitches

| The PC Guide

(http://www.PCGuide.com) Site Version: 2.2.0 - Version Date: April 17, 2001 © Copyright 1997-2004 Charles M. Kozierok. All Rights Reserved. |

Not responsible for any loss resulting from the use of this site. Please read the Site Guide before using this material. |